Product overview

Data collection

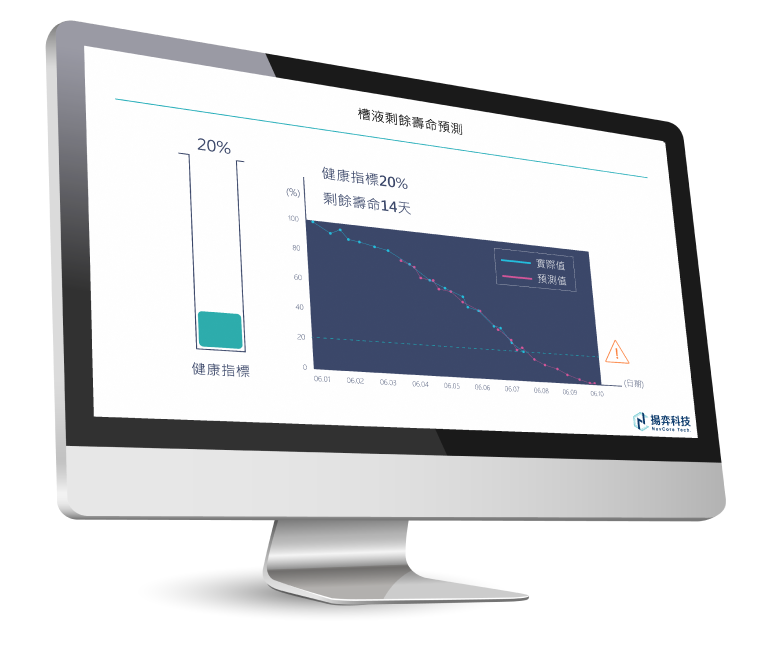

Analyzing the status of solution tanks using chemical testing data and daily production plans to predict the remaining lifespan of the solution.

AI model training

Self-development of AI algorithm model to master future reservoir liquid quality and surviving life.

Indicator of remaining lifespan

Indicators are used to understand the status of the solution tanks, determine the best time for tank replacement make maximize usefulness and reduce expenses.